This early October brought some great news that we had been looking forward to. It was news that we had been working on for several months and had been interacting with our customers to refine the details to ensure ease and impact.

We have launched a new area exclusively designed to facilitate your Monitoring Logs. We are pretty confident that this development has greatly increased the possibilities of Labinfy and the results it delivers to food industries and plants. To better understand the benefits of this new feature, let’s quickly go through the concept behind the functionality:

What are monitoring logs?

We have seen in other articles the importance of the Autocontrol Programs (CAP) for the agribusiness and how they create mechanisms and procedures that aim to facilitate the management of hazards and risks existing in the production process. Within the three main norms that make up the implementation of CAPs within companies, GMP, HACCP, and SOPs, the control of process parameters becomes an indispensable part for the success of this endeavor.

So the process starts with the creation of your Monitoring Plans related to the type of hazard, the processing step where the critical control point must be controlled, the critical limits, and the critical elements that determine the control of the hazard. After the definition of the frequency, responsible person, and the verification procedures in the company documents, you perform the monitoring records constantly to evaluate the quality conditions in production.

E é aí que o Labinfy entra para te ajudar. Na criação dos seus planos, a nova área de Registro de Monitoramento possibilita que você indique rapidamente os parâmetros de controle que serão monitorados e registrados e, a partir deles, digitalize os formulários para preenchimento dos dados. Os registros por sua vez são salvos para maior visibilidade e identificação de desvios, já com as informações de usuários, data e hora início e fim de preenchimento e com as fórmulas de determinação já calculadas.

What the new version of Labinfy offers to put this into practice:

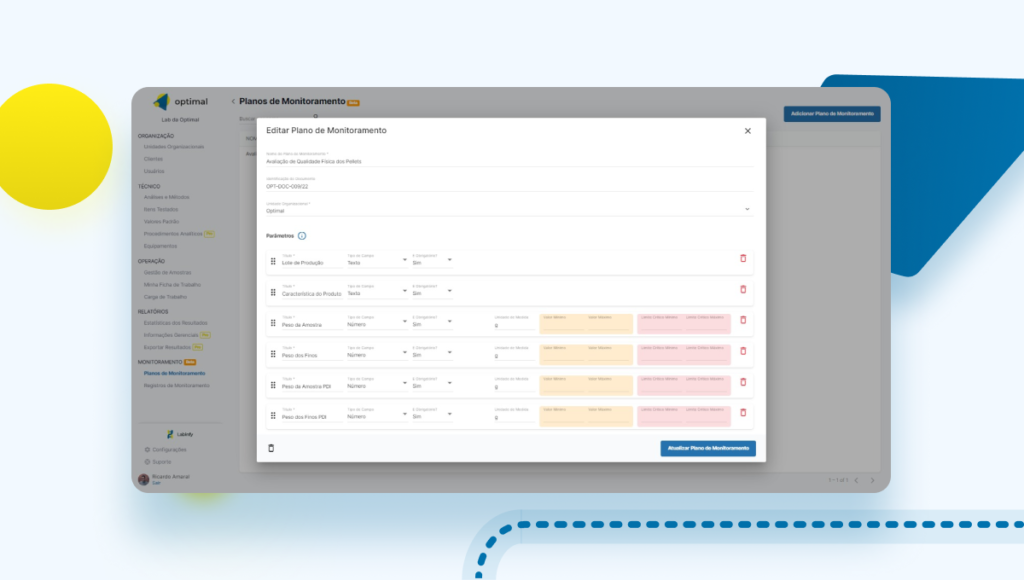

To make this function clearer, let’s assume that we are creating a Monitoring Plan to obtain physical quality pellets from commercial feed. To evaluate the durability and quality of the pellets we will use the Pellet Durability Index (PDI) and Fines Percentage (FOB) method.

So, you can create a text parameter to indicate the monitored lot, a parameter to indicate the characteristics of the feed (such as whether it is bagged or bulk) and we can create 2 formulas: one for Fines Analysis and another for PDI. Thus, we would have the following structure:

Plano de Monitoramento: Avaliação da Durabilidade e Qualidade Física dos Pellets

Parâmetro 1: Lote de Produção

Parâmetro 2: Característica do Produto

Parâmetro 3: Peso da Amostra

Parâmetro 4: Peso dos Finos

Parâmetro 5: Peso da Amostra PDI

Parâmetro 6: Peso dos Finos PDI

Parâmetro 7: Análise de Finos = ( [Peso dos Finos] * 100) ) / [Peso da Amostra]

Parâmetro 8: Análise de PDI = ( [Peso da Amostra PDI] – [Peso dos Finos PDI] ) / ( [Peso da Amostra PDI] * 100 )

Important: when entering a parameter with formula, everything that is inside a group of brackets [ e.g. PARAMETER NAME ], Labinfy recognizes it as the name of another parameter previously listed. In other words, if you want to list parameters in determination equations, just make sure that the parameter’s name is exactly the same as the one listed for the same monitoring plan.

Still in this Plan, let’s assume that for the Pellet Durability Index (PDI) we are aiming for a feed production above 95% d and PDI. For this, let’s define that for the PDI Analysis we have a Minimum Value of 95% c as a criterion that separates acceptable values from unacceptable ones.

However, we know that variability is normal in any production process performed – that is why continuous monitoring and calibrations aim to decrease this variation. If you want to set a further critical safety limit, as a way to adopt a stricter standard, you can set a Minimum Critical Limit of 93%, thus leaving a warning to correct the process.

Creating New Monitoring Records

Once your Monitoring Plans have been created, you can start your records. As the menu itself makes clear, we will use the Monitoring Records area for this. On accessing it, you will see that at the top you will have a selection list – this is your first step: select the Monitoring Plan you want to add or check the records for.

As soon as you select it, the table will open with all the records already made and the information not only of the data that was monitored, but also the date it was created and the user responsible for creating it. You can not only have a wide view, but you can also click the Export button to have an Excel spreadsheet with all this data.

To open a registration form, click the Add Monitoring Record button at the top right. As soon as you do, the window for you to enter data will open automatically – just fill in the correct fields and then click the Add Monitoring Record button. Automatically a new row with the record will be inserted into the table and all the formula parameters created will be automatically calculated and filled in.

To further facilitate the visualization of data that are outside the values and limits that you have defined, you will see that Labinfy itself will mark the field in orange if it is not within the limit value and in red the data that have exceeded the critical limits defined. This view speeds up the identification of parameters that can bring risks and deviations to your process and facilitate faster decision making.

Streamline monitoring logs in a secure manner

If you have any questions or need assistance from our team to set up your company’s Monitoring Plans, please contact our Support team and they will be happy to help you register everyone along with you.

Por enquanto, as funções de Monitoramento estão em beta, ou seja, nesse período elas ficarão disponíveis para todos os clientes testarem e darem o seu feedback e sugestão. Após isso, elas serão incluídas no plano PRO do Labinfy. Se você já é nosso cliente e utiliza esse plano, automaticamente e sem nenhum adicional, elas estarão disponíveis para uso. Converse com nosso time para saber como aproveitar ainda mais a funcionalidade.

If you are not yet a customer, click here to open a free Labinfy account and start digitizing your company’s laboratory activities.