From quality control to least cost formulations — all connected.

Increase the operational efficiency of your production, cut costs, and meet the growing demands for high-quality, safe, and nutritionally precise products. Powerful solutions on their own, even better together.

Optimal has the trust of thousands of users for more profitable operations through data optimization.

PRECISION FORMULATION IN PRACTICE

The easiest and most powerful way to optimize feed and food formulation

Feed, food, and pet food companies have the crucial mission of creating products that meet guarantee levels and optimal nutritional needs. Optimal's software allows them to automate quality controls, reduce production costs with optimal formulas, and enables teams to work together effortlessly.

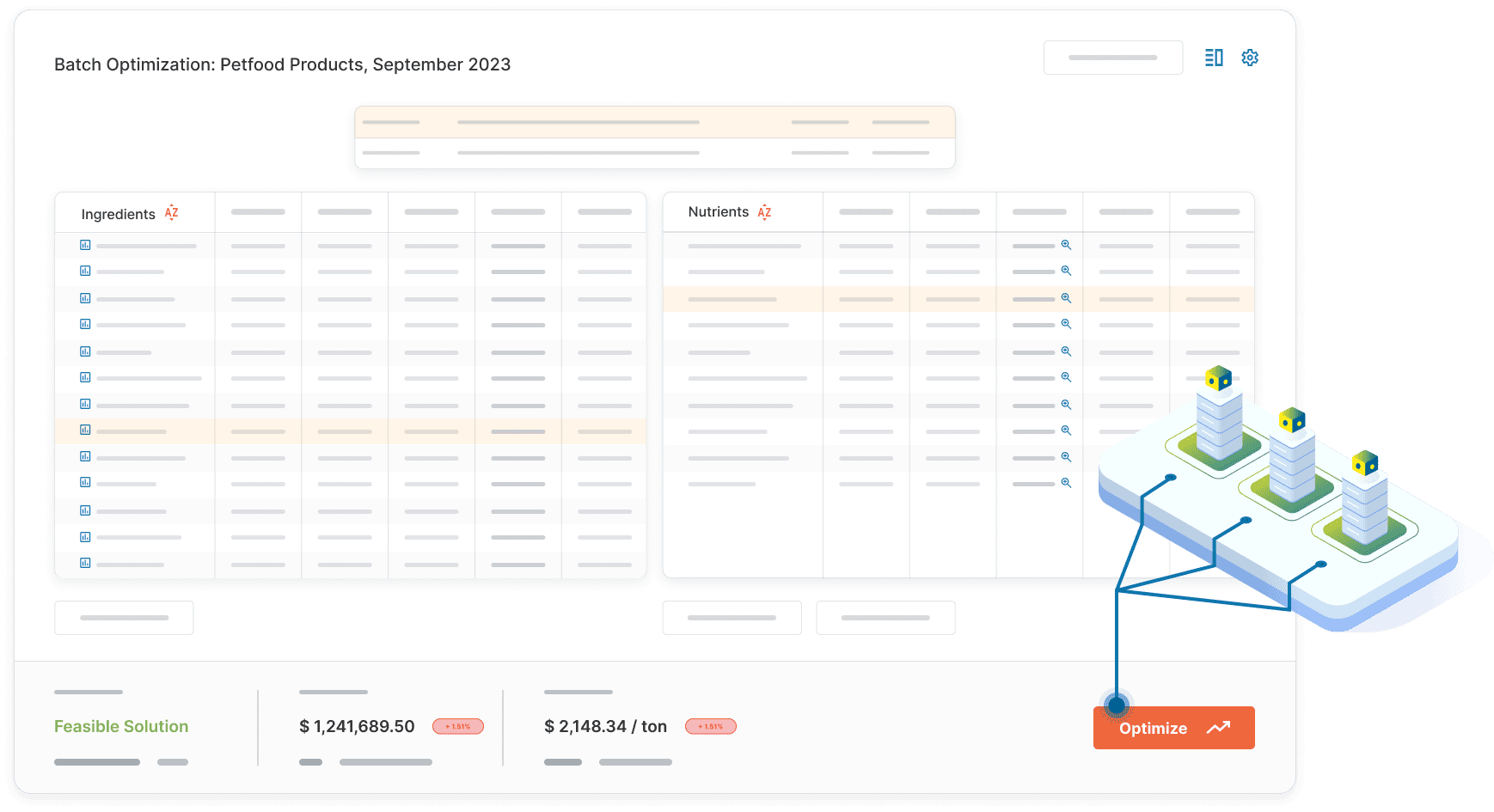

Least cost formulas in seconds

Create formulas for any animal species or commercial products quickly, efficiently, and with simplicity, ensuring the lowest possible cost per ton produced in your factory.

Laboratory data and quality management

Manage analytical results from samples, import data from NIRs and amino acid analyses, and maintain an always-active and easily accessible record to monitor process parameters.

FORMULA OPTIMIZATION

Optimize feed and food formulas for better results

Quickly create one or multiple formulas that meet the necessary nutritional requirements and recommendations at the lowest possible cost. Optimal's software allows you to create and adapt product formulations that provide the required nutrients in the most economical way, without compromising operational efficiency and the quality of the finished product.

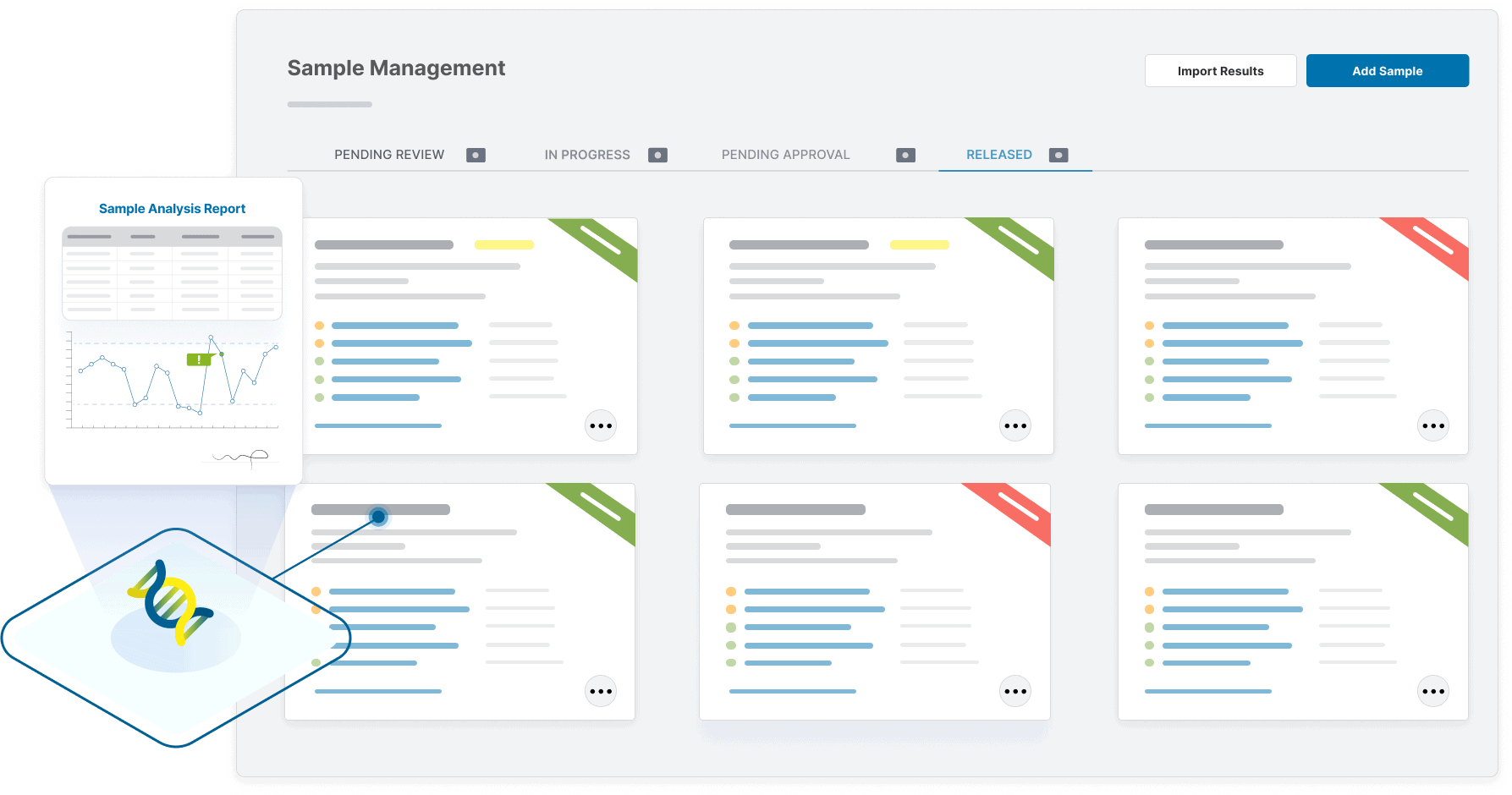

LABORATORY DATA MANAGEMENT

The easiest way to manage NIR and laboratory data

Manage the entire life cycle of samples, import results from NIR equipment and amino acid analyses, perform comprehensive statistics to generate updated nutritional matrices, and issue digital reports in just a few clicks with the Labinfy laboratory management platform — be it wherever you are and at any time.

SIMPLIFIED DATA MOBILITY

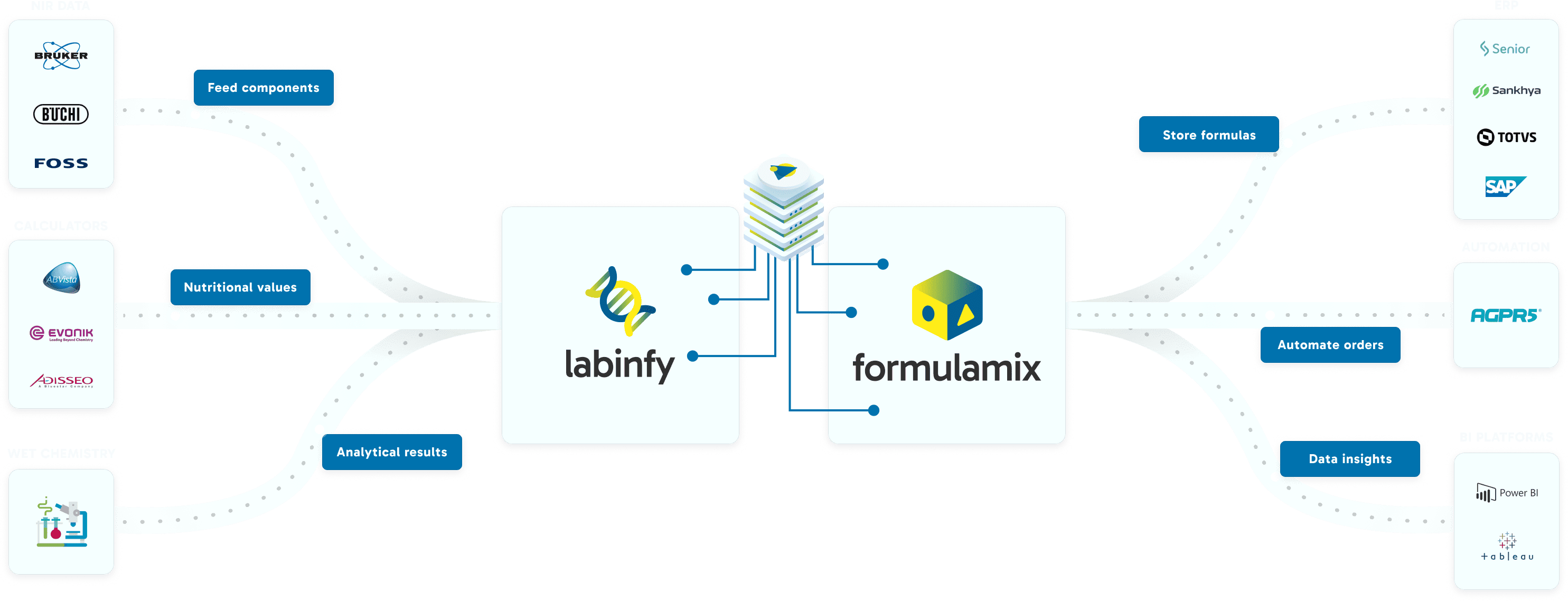

Integrate your workflows with management systems and industrial automation

Optimal's software is designed to reduce complexities and provide optimized solutions. Built with the latest and smartest tools, your team can quickly unify different solutions via API without unnecessary hours and costly customizations, reducing risks associated with manually transferring spreadsheets and data from one system to another.

30+ YEARS HELPING TRANSFORM AGRIBUSINESS

On a mission to simplify and make precision formulation more accessible for the feed and food industry

When it comes to precision formulation, cloud-based technologies that easily communicate with other software are indispensable. This seemed to be something limited to large corporations with million-dollar budgets and large teams. But it doesn't have to be that way.

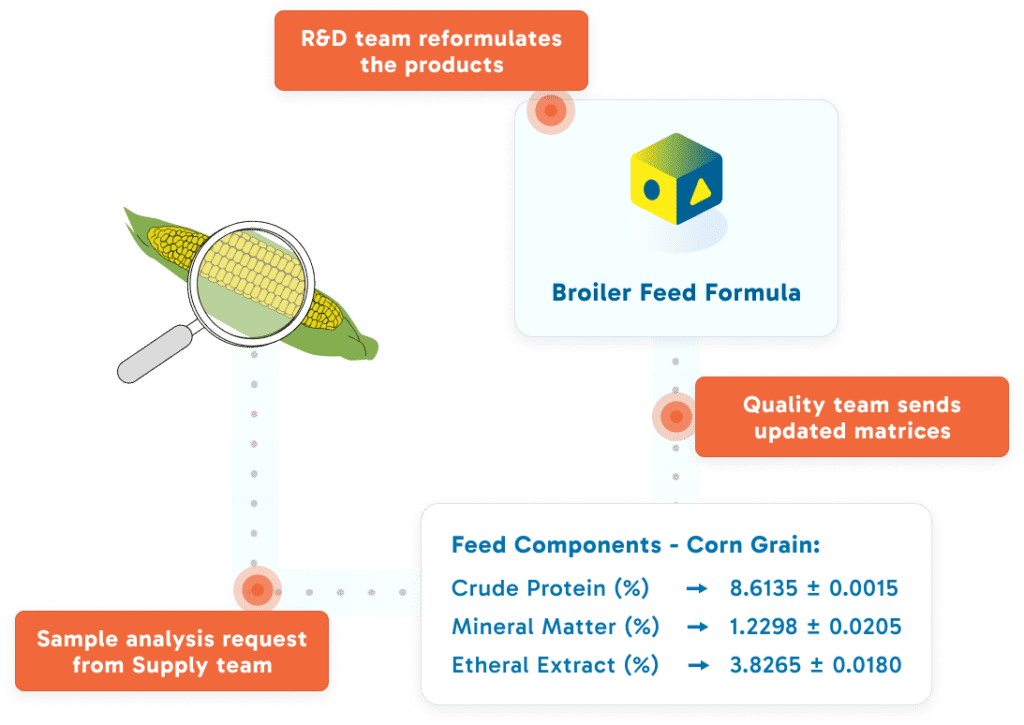

Optimal's software allows for the collection of large amounts of data from different sources through Labinfy, such as wet chemistry, NIR, and amino acid analyses. It calculates nutritional matrices with more accurate information and sends this data to Formulamix, which, in turn, allows for the reformulation of a specified product more quickly. This dramatically reduces the time between formulation and production, enabling better decisions at the exact moment they need to be made.

5M+

optimized formulas every year

2M+

analyses recorded per year

1M+

tons produced per month

COLLABORATIVE FORMULATION DEVELOPMENT

Tools designed for teams to align with company objectives

Optimal's tools integrate to enable teams of all sizes to create and collaborate for better results. Whether managing laboratory information, NIR data, or optimizing formulations, the software is designed to provide each area with relevant information and insights for more precise decisions. This approach allows for more scalable processes, smarter workflows, and a greater focus on meaningful work.

Obtain comprehensive data statistics for parameter validation and nutritional value definition

Collaborate in real-time across teams in different locations, units, plants, and laboratories

Quickly adjust your formulation based on cost fluctuations and raw material availability

Maintain a complete history of produced formulas for valuable insights and analysis

Explore the new standard for laboratory data management and precision formulation

Transform the way you handle data from your laboratory, NIR equipment, and how they communicate with the formulation. From anywhere, at any time.